Workplace safety is a critical priority for organizations worldwide. ISO 45001:2018, the first global standard for occupational health and safety (OH&S) management systems, provides a framework to proactively improve safety, reduce workplace risks, and create safer working environments.

In this article, we’ll explore the essentials of ISO 45001:2018, its benefits, implementation steps, and practical tips to enhance workplace safety and achieve certification. Whether you’re a safety manager or a business owner, this guide will help you understand the value of ISO 45001:2018 and how to make it work for your organization.

What Is ISO 45001:2018?

ISO 45001:2018 is an international standard for OH&S management systems, replacing the previous OHSAS 18001. It helps organizations of all sizes and industries create safe workplaces by:

- Reducing occupational risks.

- Preventing work-related injuries and illnesses.

- Promoting employee well-being.

The standard follows the High-Level Structure (HLS), aligning it with other ISO management standards like ISO 9001 (Quality Management) and ISO 14001 (Environmental Management), making integration seamless.

Why Is ISO 45001:2018 Important?

Workplace accidents and illnesses not only harm employees but also result in financial losses and reputational damage for businesses. ISO 45001:2018 addresses these challenges by fostering a culture of safety and accountability.

Key Benefits of ISO 45001:2018

- Reduced Workplace Incidents Proactive identification and mitigation of hazards minimize accidents and injuries.

- Regulatory Compliance The standard helps organizations comply with legal and regulatory requirements, avoiding fines and penalties.

- Improved Employee Morale A commitment to safety fosters trust and confidence among employees, boosting morale and productivity.

- Cost Savings Fewer incidents lead to lower insurance premiums, reduced downtime, and cost savings.

- Enhanced Reputation Certification demonstrates a commitment to safety, attracting customers, partners, and top talent.

- Global Recognition ISO 45001:2018 is an internationally recognized standard, ensuring consistency in safety practices across borders.

Key Principles of ISO 45001:2018

ISO 45001:2018 is built on several core principles:

- Leadership Commitment Top management must take responsibility for integrating OH&S into the organization’s culture and operations.

- Worker Participation Employees at all levels should be actively involved in identifying hazards and developing safety solutions.

- Risk-Based Approach The standard emphasizes identifying, assessing, and managing risks to prevent incidents.

- Continual Improvement Organizations must regularly evaluate their OH&S performance and strive for ongoing enhancements.

Steps to Implement ISO 45001:2018

- Understand the Standard

Familiarize yourself with the requirements of ISO 45001:2018 and how they align with your organizational goals. Training sessions or workshops can be helpful.

- Conduct a Gap Analysis

Assess your current OH&S practices to identify gaps between existing processes and ISO 45001:2018 requirements.

- Secure Leadership Commitment

Top management’s support is crucial for effective implementation. They should allocate resources and demonstrate commitment to safety.

- Identify Risks and Opportunities

Analyze your workplace to identify hazards, assess risks, and explore opportunities to improve safety.

- Develop an OH&S Policy

Create a clear policy outlining your organization’s commitment to occupational health and safety, with measurable objectives.

- Implement the Management System

Establish processes for hazard identification, risk assessment, training, communication, and incident reporting.

- Train Employees

Educate employees on their roles in maintaining a safe workplace and adhering to the OH&S management system.

- Monitor and Evaluate

Track key performance indicators (KPIs) like incident rates, near-misses, and audit findings to evaluate the system’s effectiveness.

- Conduct Internal Audits

Regular audits help identify non-conformities and ensure continuous improvement.

- Certification Audit

Engage a certification body to assess your OH&S management system and issue the ISO 45001:2018 certificate upon compliance.

Examples of ISO 45001:2018 in Action

Case Study: Construction Industry

A construction company implemented ISO 45001:2018 to address high workplace risks. By introducing robust risk assessments and safety training, they reduced accident rates by 40% within a year.

Case Study: Manufacturing Sector

A manufacturing firm adopted ISO 45001:2018 to improve machine safety. Regular maintenance schedules and employee training significantly reduced equipment-related injuries, enhancing operational efficiency.

Practical Tips for ISO 45001:2018 Implementation

- Use Technology Leverage safety management software to track incidents, automate reporting, and analyze trends.

- Engage Workers Foster open communication to encourage employees to report hazards and participate in safety initiatives.

- Customize Processes Tailor the OH&S management system to your organization’s specific needs and risks.

- Focus on Training Regular training ensures employees understand safety protocols and how to respond to emergencies.

- Set Realistic Goals Start with achievable safety objectives and expand efforts as your system matures.

Challenges in Implementing ISO 45001:2018

- Resistance to Change

Employees may resist new safety processes. Overcome this by explaining the benefits and involving them in decision-making.

- Resource Constraints

Small organizations may face financial or staffing limitations. Prioritize high-risk areas and scale efforts over time.

- Continuous Compliance

Maintaining compliance requires ongoing effort. Schedule regular audits and reviews to stay on track.

Conclusion

ISO 45001:2018 is more than just a standard—it’s a pathway to safer, healthier workplaces. By implementing this framework, organizations can protect their employees, enhance their reputation, and achieve long-term success.

Whether you’re just beginning your ISO 45001 journey or looking to optimize your existing system, this standard provides the tools to transform your approach to occupational health and safety. Commit to safety today, and pave the way for a brighter, safer future.

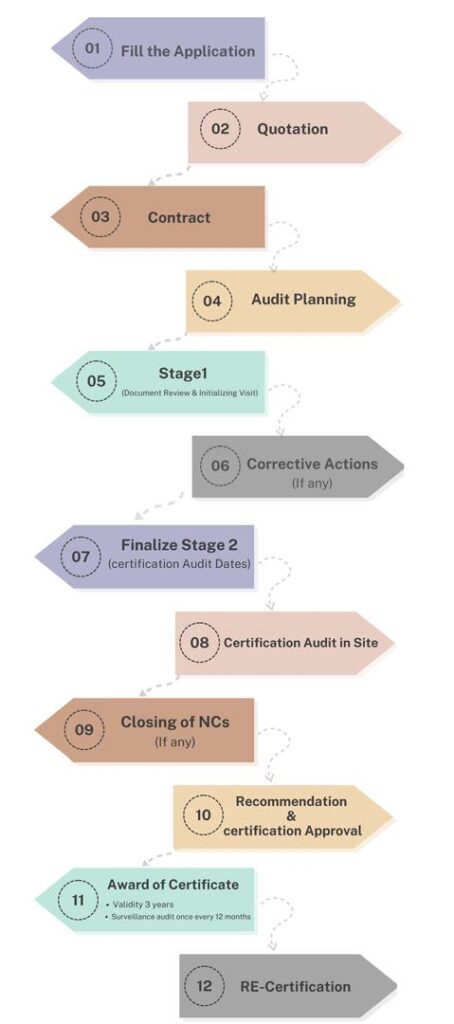

Certification Process

1- Completion of information related to the company name, company activities, the number of staff per work shift, website address, and branches.

2- Announcement of costs related to the requested certification issuance process.

3- Preparation and approval of the contract for implementation.

4- Planning the audit process and notifying the client for audit process.

5- reviewing documents to identify the client strengths and weaknesses in comparison to the established documentation.

6- Corrective actions for potential weaknesses.

7- Final planning for conducting the audit, registration, and certification issuance.

8- Conducting the on-site audit process at the client by the specialized team of the certifying company.

9- Corrective actions for potential weaknesses in the execution of the organization’s processes.

10- Recommendation for the issuance of a certification related to the client to the head office.

11- Achieving the related certification.

12- Renew after three years.